Everything You Need to Know About Electronic Product Design

Developing your idea into a new product can be a fun and rewarding process. The measures outlined below will take you from concept to fully functional prototype. However, once the prototype is complete, there are still a number of steps to take before a product is ready to produce and sell.This article aims to highlight the five essential steps involved in creating a design for a new electronic item.

1.Start With the Schematic

While the development of a Printed Circuit Board is the ultimate aim of electronics design, your first step should be designing the circuit schematic. Think of a schematic as being similar to a house blueprint. These can be drawn up using schematic software. The first step in designing the schematic circuit is to conduct preliminary research to determine the best topology and most cost-effective components. Running simulations and breadboarding can also be included (used only rarely in modern electronics). At this point, you should also make a list of parts for your project. These parts can be found at some electronics companies.

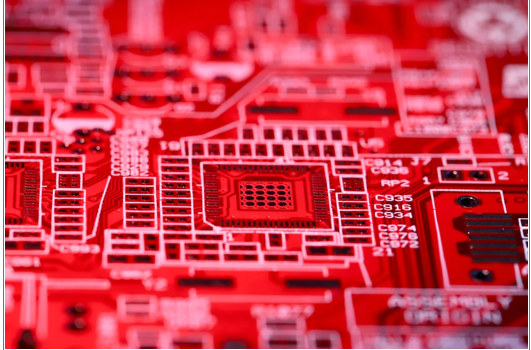

2.Develop the PCB

While some boards can be routed automatically, most boards need manual routing for optimal efficiency. For power and RF circuits (Bluetooth, WiFi, GPS, etc.), the PCB layout is extremely sensitive, and errors on the PCB in these areas are normal. When the PCB layout is finished, the design program will inform the designer whether or not the PCB suits the schematic. It will also review wire widths, trace spacings, and other parameters to ensure that the layout complies with all of the rules for the PCB fabrication process in question. It will be important to get all of the specifications for your PCB manufacturer’s method before starting the PCB layout. Each PCB shop has its own set of requirements for its manufacturing process. It’s time to submit the data to a PCB store for prototyping once the design is done. The boards should arrive in 1-2 weeks. Or you can sometimes pay extra for rush shipping.

3.Debug Your Circuit

When the prototype is returned, it will need to be tested, and any issues discovered must be debugged. Ideally, there will be no issues, but this is exceedingly rare, and there will almost always be at least a few. Debugging your circuit is a tough process to predict because you can’t decide how long it will take to repair it before you know what the problem is.

4.Microprocessor Programming

Almost all electronics items today contain a microcontroller that serves as the product’s brain. These are almost always written in the “C” programming language. Sections of the software can be written in assembly language if it needs to be extremely efficient or fast. The programming is sometimes performed by the same person who designed the circuit, but it is usually done by a software specialist.

5.Create the Enclosure

Almost always, this is done by an engineer other than the one who handled phases 1 through 4. At first, all you need is a 3D modeling expert, particularly if you already have a good idea of how your product should look. To make it look fine, you may want to employ an industrial design engineer at some point. Industrial designers, for example, are the engineers who make Apple’s products look so slick. In any case, make sure whoever creates the 3D model has experience with injection molding. Injection molding is used for high-volume production, while 3D printing is used for low-volume prototyping. Make sure to specify to your designer to create a model that can be both 3D printed and injection molded.

Once you have your working prototype, it’s time to patent it and start production!

Check Next >https://www.neoadviser.com/how-to-change-your-apple-id-password-ios-10-3-and-up-macos/