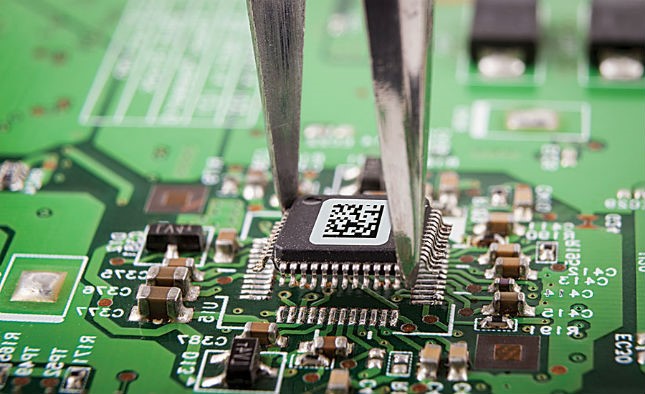

You have decided to create your own printed circuit board and you have just completed the design? What’s next? According to the professionals at East End Assemblies there are a couple of things to check before submitting the design. All of them are mentioned below.

1. Check gerber files and are they loading properly

This tip is mandatory for all beginners and newbies. In general, you will have to check the gerber files and to see are they loading properly. To check this, use another software such as View Mate. It is free and it can help you load the gerber files without the native software. If all the elements are fine, you are good to go.

2. The minimum width and spacing

Now you need to check the width and spacing requirements. They will vary depending on the provider you have selected but most of them offer 4 mm width and 3 mm spacing of trace.

Just to make sure, contact them once again and check does your project meets the requirements that have been set.

3. A layer of the board outline

You need a layer of the board in order to allow the manufacturer to be able to cut a board without any trace lines. This is a helpful process and we can see many variations. Some brands will allow you to set the components 8mm away from the edge while others have different specifications. Once again you need to check with the guys responsible for your board printing and then more to submitting.

4. Is the centroid file available?

The centroid file is used to provide instructions to the machines on where to pick up the pieces and where to set them on board. If you are planning an automated construction and production you need this file and it is more important than you may believe. Always make sure it is included in the design.

5. Availability of your components

Make sure that all parts and components are available for purchase and order at any given moment.

By doing this, you won’t have to wait for the sellers to obtain the parts and production can start immediately. It is one of the simplest tips that have a huge, positive effect on the overall simplicity and the end result in general. It goes without saying that you need to perform the check for all parts and all components that are planned.

6. Is your drill file ready?

The file instructs the machines where to drill holes on the board. They need to be added to the overall design and they have to be added separately in some cases. This is mandatory and you need to check it as soon as possible.

Check Everything Before Submitting your PCB Design

Performing all of these checks is a simple and straightforward task that can cost you a few minutes of your time. In return, your project will be safe and solid. You will be able to start working on it immediately.