Introduction:

Woodworking is one of the most important and dangerous jobs. Even if it sounds simple, there are several accidents which might ruin your day. So, we will recommend you to follow safety precautions in order to prevent unwanted accidents. In this article, we will discuss a few of the basic safety rules which will guide you to deal with several hazards which might happen in your workshop. As a woodworker, you should definitely need to deal with hazards while working with dangerous tools.

1. Wearing eye protection:

Eye protection is much needed while working in the workshop. You need to use safety glasses, face Shields hot goggles in order to protect your eyes from flying wood chips, broken tool parts, sparks, and abrasives from grinders and splashes from solvents or any finishes. Safety glasses are needed for the protection against small chips or any small workshop hazards. Safety goggles are the best kind of protection against chemical splashes. And the face Shields need to be used while working with cordless Mini circular saws. It is recommended to use safety classes underneath the face shields for protection.

2. Wearing respiratory protection:

Another much-needed protection is the respiratory protection, for this purpose you can use washable cloth mask, disposable mask, powered air respirators, and half-facepiece respirators. Disposable masks are used for protection against dust particles, whereas washable face mask can protect you from even a moderate amount of dust. Power air respirators are having fans which are battery powers which continuously filters the air.

This option is the most expensive compared to any other respiratory protection options. Half-facepiece respirators are having replaceable cartridges which filter the dust particles or any kind of vapours. These respirators are approved by NIOSH, which is a federal government regulatory agency.

3. Using dust collectors:

Dust collectors are used for collecting food just after the project is completed. key of the workshop revenues vacuum cleaners for completely cleaning out the wood dust. In order to clear the ambient dust in the air of the shop, you need to use Air filtration system which is powered by electricity.

4. Wearing hearing protection:

While working in the workshop, loud noises are created by using different kinds of tools in the materials. Sometimes excessive noise can cause permanent damage to your eardrums. In order to prevent hearing loss, we would recommend you to wear earplugs or over ear muffs. There is a level of allowed noise exposure while unprotected before it can damage your hearing.

If you are using drill press the actual noise level is 92 decibels, which can be allowed up to 6 hours. Using a shop vacuum, it is having a noise level of 95 decibels and allowed only for the four hours of exposure. Drum sander makes 97 decibels of noise and 3 hours of exposure is allowed. Wood planer creates 102 decibels of noise level and can be allowed for 1.5 hours.

Circular saw creates noise for 105 decibels, and only one hour of exposure is allowed. Whereas Chain Shaw makes 110 decibels and power-driven nail gun makes 140 decibels of noise. So, they definitely require hearing protection for users.

5. Wearing protective footwear:

The workshop can be messy while working with various kinds of materials. So you definitely need to wear protective footwear while standing on the floor for hours of work. The basic requirement for usage of the protective footwear is for preventing the strain of standing in the solid floor. It is recommended to wear leather boots for protection against cuts from accidental drop off dangerous tools in the workshop.

Steel toe shoes are used for protecting your feet from getting crushed from any hard or heavy materials slipped from the hands while working. It can even protect you from several heavy tools which are used in the workshop, which includes a hammer or even the entire toolbox.

6. Wearing tight clothes and jewellery:

It is recommended to use short sleeves while working in the workshop, as most of the time long sleeves can get entangled with several tools. Even spinning blades can get Tangled with the long sleeves and cause an accident in the workshop. In case you are wearing long sleeves, we will ask you to roll them up for better protection. Jewellery is forbidden while working in the workshop with tools, jewellery tends to get caught in several dangerous tools which are the main cause of hazard in the workshop.

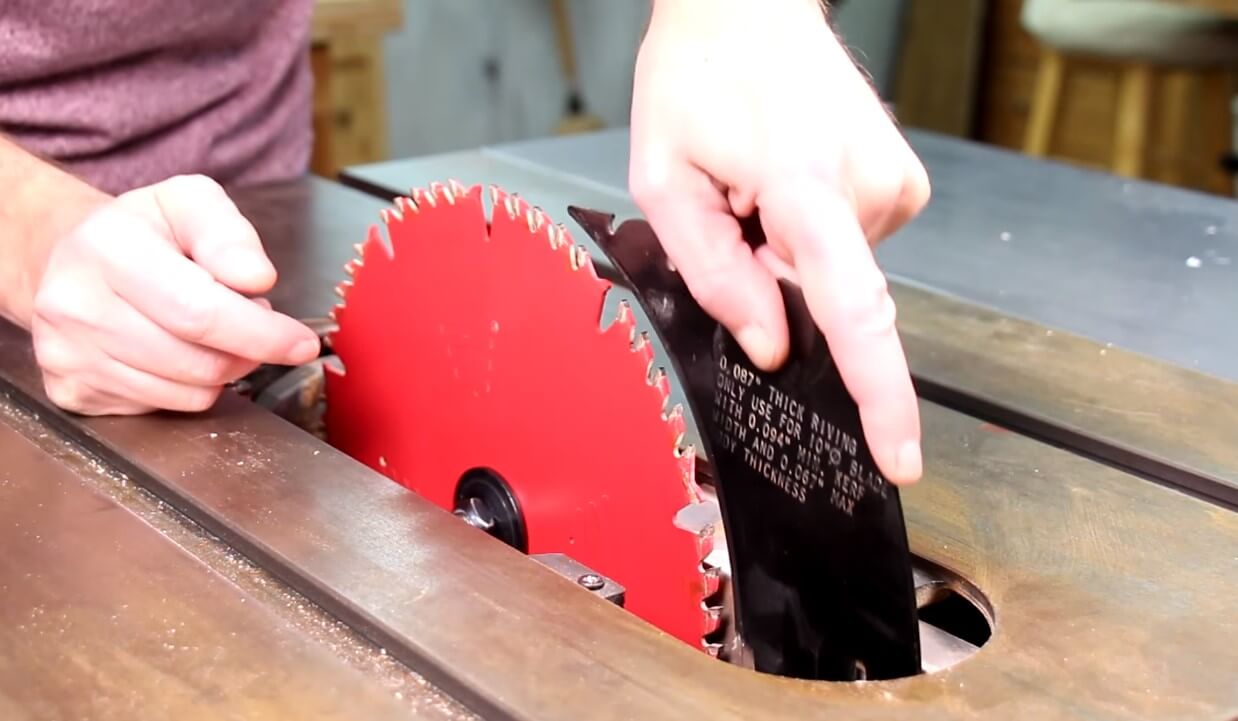

7. Using machine guards:

Most common mistakes done by woodworkers are the removal of machine guards. Even a study performed by CPSC confirmed that over 65% of the woodworkers remove the blade guards. As a result of the end up having a serious case of injury while using saws. The most common reason for the removal of the blade guard, as it gets caught in the way while working. Whereas it is rather debatable, but it is better to keep the blade guard in order to prevent any accidents in the workshop.

8. Using anti-fatigue mats:

We would recommend you to use anti-fatigue mats in order to decrease the chance of having negative health effects. As standing in the hard-concrete code for hours can cause problems on the feet in the spine. Anti-fatigue mat will prevent you from this issue.

Conclusion:

Following the safety precautions in your workshop will help you to avoid several hazards. Safety precautions are a must in each and every production field, so you should definitely follow the guidelines which we have provided in this article. We have gathered complete information about the safety precautions and prevention of hazards from various sources and posted them in this article for you. You can get further information from Firstwoodworker, which will be rather interesting for you to work with. Share this useful article with others, so that take it you know about the safety precautions which need to be taken while working in the workshop.